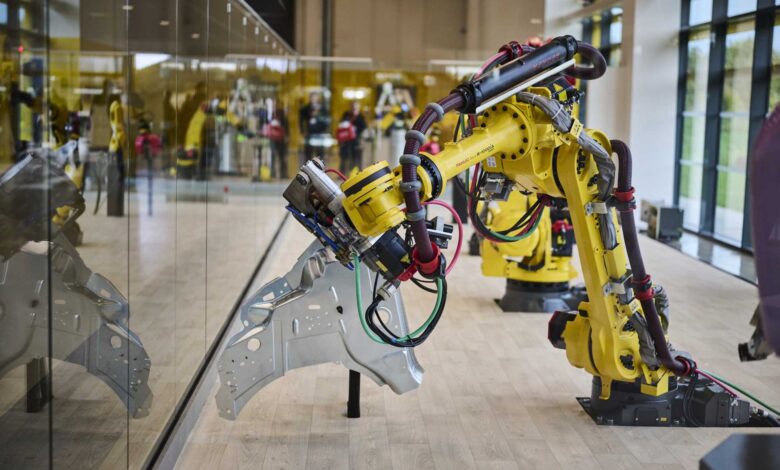

In the realm of modern manufacturing and industry, the term “industrial robots” has become increasingly prevalent, representing a technological revolution that is transforming the way we produce goods. These automated machines have become integral components of the manufacturing landscape, driving efficiency, precision, and innovation. In this article, we delve into the world of industrial robots, exploring their definition, applications, and the impact they have on various industries.

Defining Industrial Robots

Industrial robots are automated machines designed to carry out tasks traditionally performed by human workers in industrial settings. These machines are equipped with advanced sensors, actuators, and control systems, allowing them to perform a wide range of activities with speed, accuracy, and repeatability. Unlike traditional manufacturing machinery, industrial robots have the ability to adapt to changing conditions, making them versatile assets in diverse industries.

Key Characteristics of Industrial Robots

- Automation and Repetition: Industrial robots excel in tasks that require high precision and repetition. They can tirelessly perform the same operation with minimal deviation, enhancing production consistency.

- Versatility: These robots are designed to handle various tasks, from assembly and welding to material handling and quality control. Their versatility makes them adaptable to different manufacturing processes.

- Programmability: Industrial robots can be programmed to execute specific tasks, allowing manufacturers to reconfigure them for different production requirements. This programmability adds flexibility to manufacturing processes.

- Sensors and Vision Systems: Advanced sensors and vision systems enable industrial robots to perceive their environment, ensuring accurate execution of tasks and facilitating interaction with human workers.

Applications of Industrial Robots

- Manufacturing and Assembly: The primary domain of industrial robots is manufacturing and assembly. They play a crucial role in tasks such as welding, painting, and assembling components on production lines. This application reduces labor costs and improves efficiency.

- Material Handling: Industrial robots excel in material handling tasks, including picking, placing, and sorting. In warehouses and distribution centers, robots streamline logistics operations, optimizing the movement of goods.

- Welding and Metal Fabrication: Robots equipped with welding tools are commonly used in the automotive and aerospace industries for precise and efficient welding of metal components. This application enhances the quality and consistency of welds.

- Packaging and Palletizing: Industrial robots are employed in packaging processes, accurately placing products in boxes and optimizing the packing of goods. They also contribute to palletizing tasks, efficiently stacking products for shipping.

- Quality Control: With advanced vision systems, industrial robots can inspect products for defects, ensuring high-quality standards. This application is crucial in industries where precision and quality are paramount.

- Collaborative Robotics (Cobots): A recent trend in industrial robotics is the development of collaborative robots, or cobots, which can work alongside human workers. These robots are designed to be safe and adaptable, fostering human-robot collaboration in manufacturing environments.

The integration of industrial robots into manufacturing processes has brought about significant transformations across various industries. Some key impacts include:

- Increased Efficiency and Productivity: Industrial robots can operate 24/7 without fatigue, leading to increased production output and overall efficiency. This enhanced productivity contributes to the competitiveness of industries.

- Improved Quality: The precision and repeatability of industrial robots contribute to higher product quality. Automated processes reduce the likelihood of human errors, resulting in consistently high-quality output.

- Cost Savings: While the initial investment in industrial robots can be significant, the long-term cost savings are substantial. Robots reduce labor costs, minimize waste, and optimize energy consumption, contributing to overall cost-effectiveness.

- Safety Enhancement: Dangerous and strenuous tasks can be assigned to industrial robots, improving workplace safety by reducing the risk of accidents and injuries to human workers.

- Job Evolution: While there are concerns about job displacement, the integration of industrial robots often leads to the evolution of job roles rather than mass unemployment. Human workers may shift to more complex tasks, such as robot programming, maintenance, and oversight.

Challenges and Future Trends

Despite the numerous advantages, the widespread adoption of industrial robots is not without challenges. Some of the key challenges include:

- High Initial Costs: The upfront investment in industrial robots, including programming and integration, can be a barrier for smaller enterprises.

- Complex Programming: Programming robots for specific tasks requires specialized skills, and there is a need for user-friendly programming interfaces to democratize access to automation technologies.

- Limited Adaptability: While industrial robots are versatile, they may struggle with tasks that require a high degree of adaptability and dexterity, such as handling irregularly shaped objects.

- Ethical Considerations: As robots become more integrated into the workforce, ethical considerations arise, including issues related to job displacement, privacy concerns, and the impact on the overall well-being of workers.

Looking ahead, several trends are shaping the future of industrial robotics:

- Integration of Artificial Intelligence (AI): The convergence of industrial robots with AI technologies is unlocking new possibilities for machine learning, adaptive control, and decision-making capabilities. This integration enhances the robots’ ability to handle complex tasks and adapt to dynamic environments.

- Internet of Things (IoT) Connectivity: Industrial robots are increasingly becoming part of the broader IoT ecosystem, enabling real-time data exchange and remote monitoring. This connectivity enhances predictive maintenance, reduces downtime, and facilitates data-driven decision-making.

- Advancements in Gripping Technology: Improvements in robotic gripping technology are addressing the challenge of handling diverse objects. Soft robotics and advanced grippers enable robots to manipulate objects with varying shapes and textures.

- Rise of Service Robotics: Beyond manufacturing, industrial robots are finding applications in service industries, including healthcare, hospitality, and logistics. Service robots are designed to assist with tasks such as cleaning, delivery, and customer service.

Conclusion

Industrial robots represent a paradigm shift in the way we approach manufacturing and industry. As these automated machines continue to evolve and integrate with advanced technologies, they are poised to play an even more significant role in shaping the future of work. The challenges associated with their adoption are being addressed through ongoing research and technological advancements, making industrial robots a driving force behind the next industrial revolution. In the coming years, the collaborative synergy between humans and robots is expected to redefine the landscape of production, ushering in an era of unprecedented efficiency, innovation, and economic growth.